EV Battery Recycling Process What Really Happens to Old Batteries

9 min read Discover the intricate journey of EV battery recycling and the innovative processes behind sustainable electric vehicle waste management. (0 Reviews)

EV Battery Recycling Process: What Really Happens to Old Batteries

Electric vehicles (EVs) are transforming the face of transportation, promising a cleaner, more sustainable future. But what happens once these advanced lithium-ion batteries reach the end of their lifecycle? The process of recycling EV batteries is a complex, multilayered undertaking that not only helps reduce environmental impact but also plays a critical role in closing the supply chain loop for valuable materials. This article dives deep into the EV battery recycling process, revealing the stages involved, technologies in use, challenges, and what this means for the future of green mobility.

Introduction

If you’ve ever wondered what fate awaits the giant battery pack in an electric car once its performance dwindles, you’re not alone. While EVs avoid tailpipe emissions, their power sources come with environmental and resource demands that need addressing. As global EV adoption surges — with 10 million electric cars on the road worldwide in 2023 and projections hitting 145 million by 2030 according to the International Energy Agency (IEA) — managing battery waste responsibly is essential.

Recycling old EV batteries isn’t just about reducing landfill waste; it’s vital for recovering scarce metals like lithium, cobalt, and nickel which are critical for producing new batteries. With valuable materials often locked within these cells, effective recycling preserves resources and reduces the ecological footprint of new battery manufacturing.

Understanding EV Battery Composition

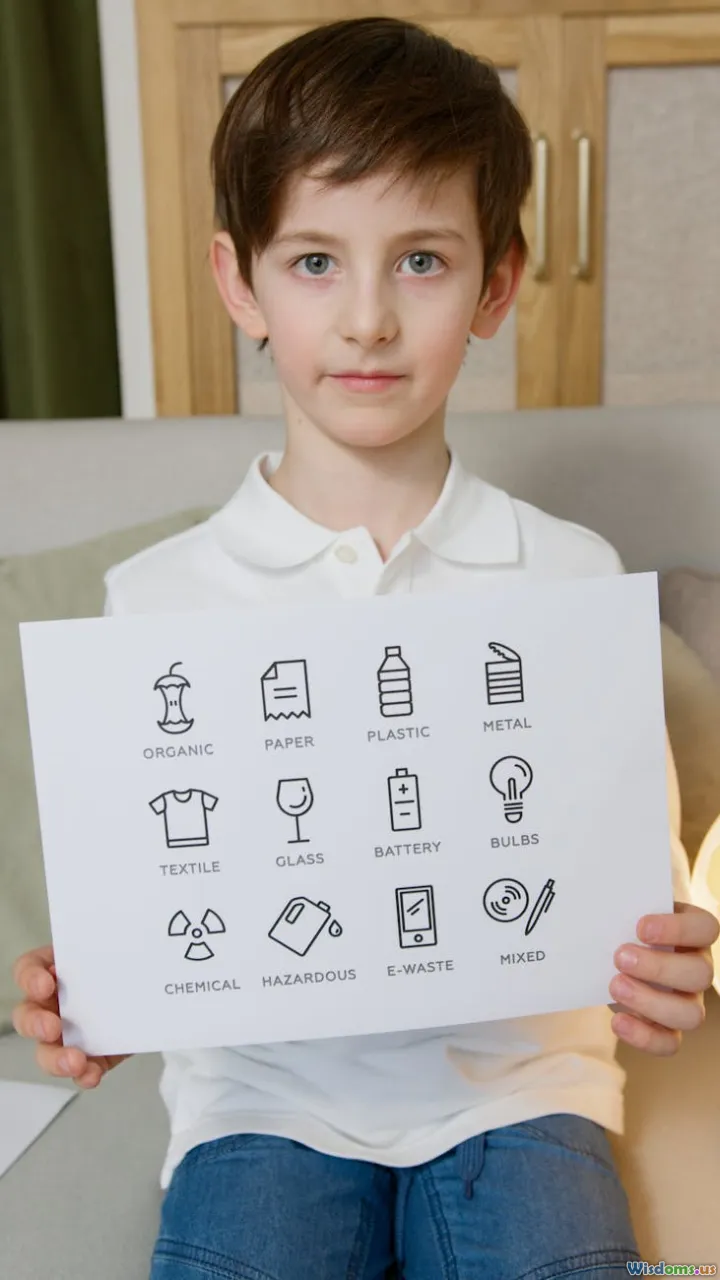

Before understanding recycling, it’s important to know what’s inside these batteries. Lithium-ion batteries powering EVs consist of several key components:

- Cathode: Usually made of lithium nickel manganese cobalt oxide (NMC) or lithium iron phosphate (LFP).

- Anode: Typically graphite.

- Electrolyte: Lithium salt dissolved in organic solvents to enable ion movement.

- Separator: Thin membrane that prevents short circuits.

These components contain valuable metals such as lithium, cobalt, nickel, and manganese that recycling targets.

The EV Battery Recycling Process Explained

The recycling process can broadly be divided into three core stages:

1. Collection and Safe Deactivation

Recycling begins with collecting retired batteries from electric cars. Before disassembly, these batteries must be safely deactivated because they retain hazardous, high-voltage energy. Manufacturers and recyclers use specialized cooling and discharge processes to neutralize remaining electricity, preventing accidental shocks or fires.

2. Battery Dismantling

Once safe, battery packs are dismantled to separate cells from modules and packs. This is often a manual or semi-automated operation due to the variability of battery designs. Sophisticated robots and lasers can be employed to carefully separate cells without damaging valuable components or causing leaks.

3. Material Recovery Techniques

The heart of recycling lies in extracting usable materials. Several methods are in play:

-

Hydrometallurgical Processing (Chemical Leaching): Batteries are shredded, and key metals are dissolved using acids and solvents. For example, cobalt, nickel, and lithium are selectively precipitated and recovered. Companies like Li-Cycle are refining this method to maximize yield with minimal environmental impact.

-

Pyrometallurgical Processing (High-Temperature Smelting): Batteries are burned at extreme heat, melting metals into alloys. This approach effectively recovers metals like nickel and cobalt but may lose lithium, requiring additional processes to recover it.

-

Direct Recycling: An emerging technique involves preserving and refurbishing the cathode material chemically without breaking it down completely, allowing reuse in new batteries. This method could dramatically reduce production waste and costs.

Real-World Examples and Innovations

Many companies and governments are racing to perfect EV battery recycling to meet surging battery volumes:

-

Tesla’s Closed-Loop System: Tesla incorporates recovered materials from used batteries back into new productions, reducing dependency on raw mining.

-

Redwood Materials: Founded by former Tesla CTO JB Straubel, this company pioneers advanced recycling technologies with reported recovery rates above 95% for key metals.

-

EU Directive: The European Union enforces regulations mandating battery manufacturers achieve a recycling efficiency of at least 65% for lithium, cobalt, and nickel, pushing industry innovation.

Such developments reduce the need for mining, decreasing environmental degradation and geopolitical supply risks associated with battery metals.

Environmental and Economic Impact

Recycling EV batteries offers profound environmental benefits:

-

Reduction of Mining Footprint: Lithium and cobalt mining have significant social and ecological consequences. Recycling diminishes the dependency on new mining operations.

-

Energy Savings: Recycled materials require considerably less energy than raw material processing. Studies estimate material recycling saves up to 90% energy compared to new mining.

-

Waste Minimization: Preventing hazardous batteries from landfills reduces soil and water pollution risks.

Economically, recovering valuable metals helps stabilize supply chains amidst volatile raw material prices. Moreover, new recycling markets create jobs, investments, and technological advancements along sustainability lines.

Challenges in the EV Battery Recycling Landscape

Despite progress, obstacles remain:

-

Design Diversity: Different manufacturers use varying battery designs, complicating uniform recycling procedures.

-

Safety Concerns: Handling energy-dense cells presents fire and toxic risks demanding advanced safety protocols.

-

Collection Logistics: Efficiently collecting and transporting end-of-life batteries requires infrastructure and regulatory oversight.

-

Economics: Low cobalt prices can sometimes make recycling less attractive financially without subsidies or regulations.

Addressing these issues requires collaboration between governments, producers, recyclers, and consumers.

The Road Ahead: Circular Economy and Sustainable Mobility

As EV adoption escalates, creating a circular economy for batteries — where materials are continuously reused — is crucial. Innovations like solid-state batteries and improved second-life applications (using EV batteries for grid storage, for instance) will complement recycling efforts.

Consumers also have a role: opting for vehicles from manufacturers committed to sustainability and supporting post-use battery programs. Policymakers must continue imposing standards and incentives to encourage recycling innovations.

The journey from old EV batteries to new, fully functional cells symbolizes a hopeful cycle of resource stewardship critical for our planet’s future.

Conclusion

The story of EV battery recycling is one of technological ingenuity and environmental necessity. Behind the sleek electric cars on roads today lies a sophisticated cycle ensuring that batteries’ end-of-life is not their end but a transformative beginning. Through advanced recovery methods, stricter regulations, and growing industry commitments, the materials powering green transportation are increasingly saved, reused, and made more sustainable.

By understanding what really happens to old EV batteries, we appreciate the deep interplay between innovation, resource management, and environmental responsibility shaping tomorrow’s mobility landscape.

Electric vehicles herald a new era — and their recycled batteries promise to keep that future vibrant and sustainable.

References

- International Energy Agency, Global EV Outlook 2023

- Li-Cycle official website

- Redwood Materials Corporate Release 2023

- European Commission Battery Directive documentation

- Tesla Impact Report 2022

Rate the Post

User Reviews

Popular Posts