Integrating Robotics into Traditional Waste Systems

8 min read Discover how robotics enhances traditional waste systems for a greener, sustainable future. (0 Reviews)

Integrating Robotics into Traditional Waste Systems: A Pathway to Sustainable Waste Management

Modern society generates tremendous quantities of waste. According to the World Bank, global waste generation is expected to reach 3.4 billion tonnes by 2050, nearly doubling from 2020 levels. As urban populations swell, traditional waste management systems are increasingly strained. The integration of robotics into these conventional systems presents an exciting, viable pathway to enhance efficiency, accuracy, and sustainability in waste handling.

Why Transform Traditional Waste Systems?

Traditional waste systems largely rely on manual labor for sorting, collection, and processing, operations often marked by inefficiency, health hazards, and environmental challenges. Manual sorting is prone to errors, leading to valuable recyclables ending up in landfills. Moreover, increasing waste volumes demand scalable, cost-effective solutions that reduce human exposure to hazardous environments.

Tom Petersen, Director of Sustainability at CleanEarth Solutions, emphasizes, “Our existing waste infrastructure cannot keep pace with today’s waste streams. Robotics not only elevates operational speed but also ensures better material recovery for recycling, dramatically reducing landfill dependency.”

Robotics in Waste Management: Core Applications

1. Automated Sorting Systems

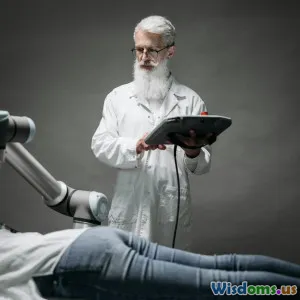

One of the most critical—and labor-intensive—phases in waste processing is sorting. Robotics-powered sorting technologies include AI-driven vision systems, robotic arms equipped with advanced grippers, and conveyor-integrated sensors. Companies like AMP Robotics employ artificial intelligence to identify, classify, and segregate waste materials with unprecedented precision.

Example: AMP Robotics’ units can differentiate between plastics, metals, cardboard, and paper with an accuracy rate exceeding 90%, even in mixed waste streams. This level of sorting enables higher recycling rates and reduces contamination—a key barrier in traditional recycling.

2. Robotic Collection Vehicles

In addition to sorting, the collection phase is evolving through robotic automation. Autonomous garbage trucks and drones are beginning trials worldwide, streamlining curbside waste collection and optimizing route efficiency.

For instance, in Oslo, Norway, autonomous refuse trucks equipped with robotic arms can pick up bins without a human operator, reducing labor costs and minimizing human exposure to traffic accidents. This technology also improves operational hours flexibility, extending waste collection beyond standard working times.

3. Landfill Inspection and Maintenance Robotics

Managing landfill sites involves monitoring greenhouse gas emissions, detecting illegal dumping, and maintaining site stability. Robots and drones equipped with sensors can perform regular inspections efficiently. NASA-inspired robots even explore hazardous landfill conditions, ensuring personnel safety while gathering critical environmental data.

Environmental and Economic Benefits

Reduced Contamination Ensures Higher Recycling Efficiency

Proper sorting facilitated by robotics minimizes contamination. The Ellen MacArthur Foundation reports contamination rates of up to 25% in recyclable materials processed by traditional methods—leading to costly waste volumes going to landfills. Robotics improves purity in recyclable streams, enabling circular economy practices.

Decreased Labor Costs and Improved Worker Safety

Integrating robotics reduces the manual handling of hazardous waste, mitigating worker injuries and sickness caused by exposure to dangerous materials or repetitive strain. From an economic standpoint, robotic automation can reduce operational expenses by 20-30%, according to a recent McKinsey report on waste logistics.

Lower Carbon Footprint

By optimizing routes for collection trucks, robotics contributes to lower fuel consumption and greenhouse gas emissions. Additionally, efficient sorting reduces material sent for incineration or landfill, lowering methane emissions associated with landfill decomposition.

Challenges and Considerations

Despite significant advantages, integrating robotics in waste systems is not without challenges:

- High Initial Investment: Infrastructure upgrades and robotics acquisition require substantial upfront capital, a barrier for municipalities with limited budgets.

- Technological Complexity: Waste streams vary drastically in composition and contamination levels, demanding sophisticated AI and sensor technologies that are still evolving.

- Job Displacement Concerns: Automation may impact frontline waste workers. Balancing technological adoption with workforce retraining and social considerations is critical.

Nevertheless, progressive collaboration between technology firms, governments, and community stakeholders has fostered pilot programs mitigating these concerns through phased implementation.

Real-World Success Stories

San Francisco’s Zero Waste Initiative

San Francisco aims to achieve zero waste by 2030. Robotic sorting is central to this goal, enabling the city to recycle and compost over 80% of its waste.

Robotics firm ZenRobotics partnered with local facilities to introduce AI-assisted sorting robots that increased recovered recyclable volumes by 25%, showing real-world impact on urban waste management.

Japan’s Advanced Waste Robotics

Japan leads in waste robotics, employing machines like the Hiro robot that autonomously sorts plastics and metals with high accuracy. The nation’s densely populated cities benefit from robotics relieving labor shortages and accelerating waste diversion from landfills.

Future Outlook: Toward Smart Waste Management Ecosystems

As renewable energy, IoT, and data analytics merge with robotics, the future of waste management promises even smarter, more responsive systems. Combining sensors in smart bins with AI-driven collection robots can optimize waste flows dynamically, reducing litter and contamination.

Governments worldwide are increasingly incorporating robotics into sustainability policies. For instance, the EU’s Circular Economy Action Plan highlights robotics as a transformative tool to achieve environmental targets.

Conclusion: Robotics as a Catalyst for Sustainable Waste Management

Integrating robotics into traditional waste systems represents a pivotal evolution that addresses both environmental imperatives and operational challenges. By enhancing sorting accuracy, reducing workforce hazards, and lowering emissions, robotics helps pave the way for sustainable, circular waste economies.

For communities and industries committed to sustainability, embracing robotics is not just an innovation—it's a necessity to future-proof waste management in our rapidly urbanizing world. Stakeholders must collaborate transparently, balancing technology adoption with equitable workforce transitions to fully realize these benefits.

As robotics continues to advance, its role in transforming waste systems only grows more vital—ushering in a cleaner, more sustainable global environment for generations to come.

References:

- World Bank, "What a Waste 2.0", 2018

- AMP Robotics Official Website

- McKinsey & Company, "The Future of Waste Logistics", 2022

- Ellen MacArthur Foundation, "The New Plastics Economy", 2021

- San Francisco Department of Environment

- European Commission Circular Economy Action Plan, 2020

Rate the Post

User Reviews

Popular Posts