The Surprising Role of Carbon Nanotubes in Electronics

15 min read Discover how carbon nanotubes are transforming electronics with unique properties, enabling faster, smaller, and more efficient devices. (0 Reviews)

The Surprising Role of Carbon Nanotubes in Electronics

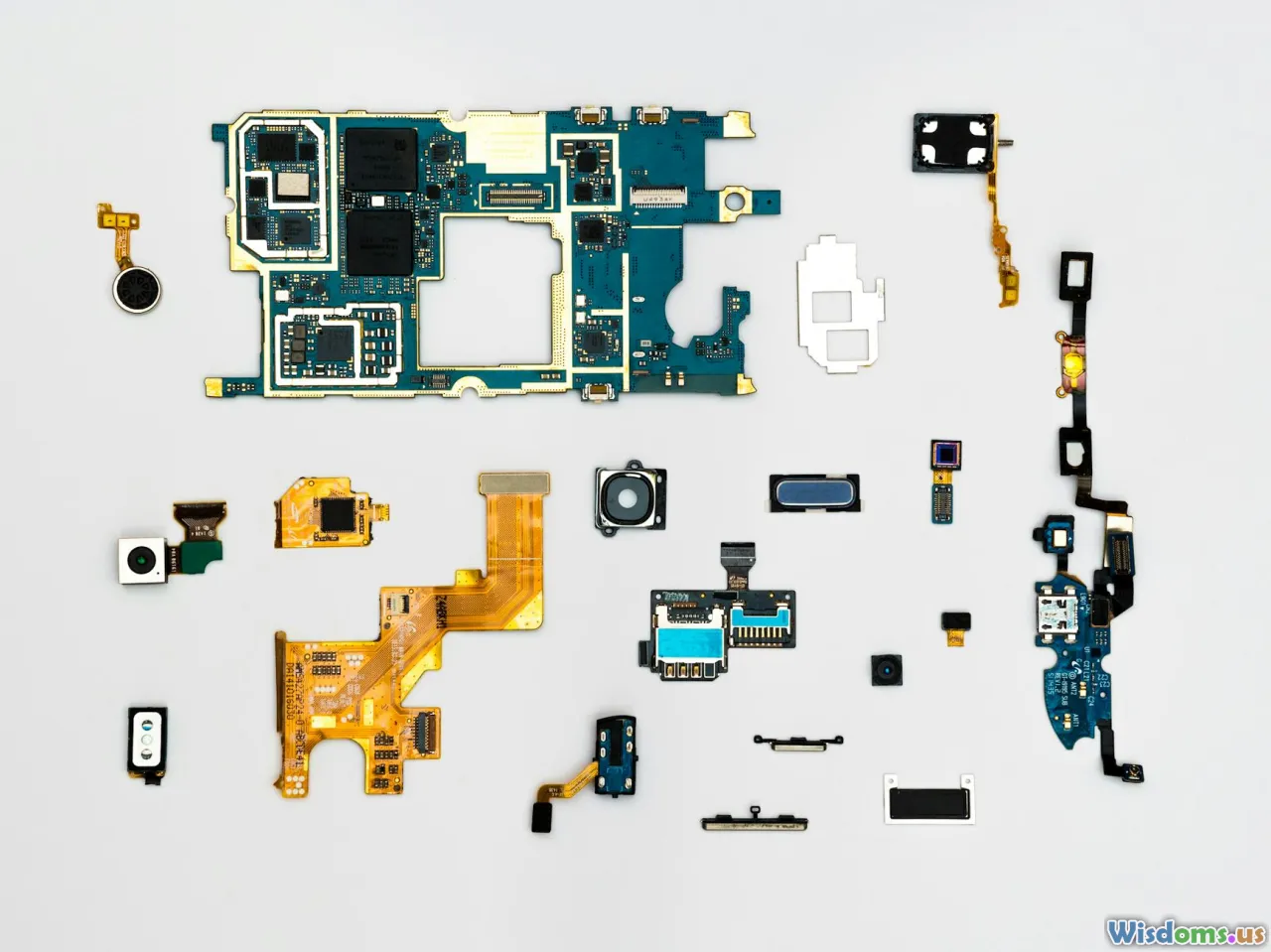

When we picture the future of electronics, it's easy to imagine transparent displays, ultrafast processors, or bendable gadgets—technologies that once seemed only possible in science fiction. Yet, at the atomic scale, a remarkable material is driving these visions into reality: carbon nanotubes. These cylindrical molecules, often thousands of times thinner than a human hair, are profoundly reshaping the ways electronic components are engineered, assembled, and imagined. But what gives carbon nanotubes their extraordinary potential, and how are they actually transforming the landscape of electronics?

What Are Carbon Nanotubes?

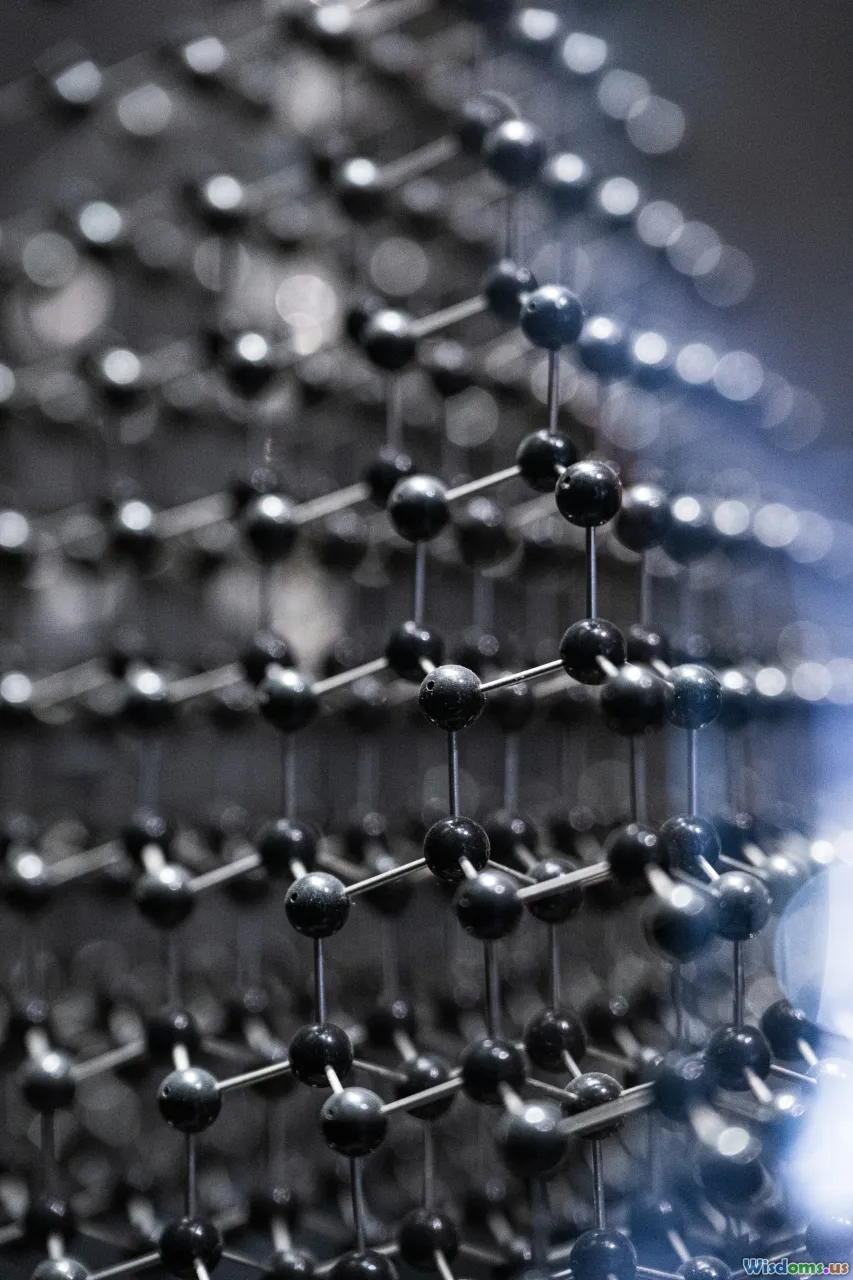

Discovered in the early 1990s, carbon nanotubes (CNTs) are cylindrical structures made by rolling graphene sheets (a single layer of carbon atoms arranged in a hexagonal lattice) into seamless tubes. These tubes typically have diameters measured in nanometers—roughly 100,000 times thinner than the average human hair. Yet despite their size, CNTs exhibit surprisingly powerful physical characteristics.

- Exceptional Strength: CNTs are 100 times stronger than steel, but with only one-sixth the weight.

- Superior Electrical Conductivity: Certain types of CNTs are as conductive as copper and can even behave as ballistic conductors, meaning electrons can travel through them without scattering, enabling nearly resistance-free transport.

- Thermal Properties: They dissipate heat rapidly, potentially solving overheating problems in miniaturized electronics.

There's a distinction to be made, however, between single-walled carbon nanotubes (SWCNTs) and multi-walled variants (MWCNTs). SWCNTs, with their tightly rolled single graphene layer, often exhibit unique electronic properties—some behave as metals, others as semiconductors, depending on how they're 'wrapped.' MWCNTs are essentially several SWCNTs nested within each other, resembling Russian dolls.

How Carbon Nanotubes Are Revolutionizing Transistor Technology

The microelectronics revolution has long been shaped by Moore's Law—the prediction that the number of transistors on a microchip will double every two years. But as we push transistors ever smaller, silicon—the old workhorse—starts to show its age. Quantum effects and excessive heat generation limit further miniaturization. Here, carbon nanotubes shine.

CNT-Based Field-Effect Transistors (CNT-FETs)

Carbon nanotube field-effect transistors (CNT-FETs) leverage semiconducting CNTs as the channel through which current flows. Because CNTs can be made extremely narrow and exhibit excellent electron mobility, CNT-FETs can outperform traditional silicon FETs in speed and energy efficiency.

For example, researchers at IBM in 2017 developed CNT-based transistors at a 5-nanometer scale that operated with far lower power consumption than any commercial silicon transistor of similar size. The compactness and efficiency of CNT-FETs could extend Moore's Law far beyond current limits, allowing for next-generation smartphones and supercomputers.

Overcoming Manufacturing Challenges

One of the primary technical hurdles with CNT transistors remains in selectively producing only semiconducting tubes (since metallic tubes short out circuits) and precisely aligning billions of individual nanotubes. Recent chemical methods and advanced lithography are making rapid progress, with laboratories reproducing aligned arrays across wafer scales—laying the foundation for industrial-scale adoption.

Flexible and Stretchable Electronics

Wearable health monitors, skin-like electronic tattoos, or roll-up digital screens might seem futuristic, but the magic behind these devices is often enabled by carbon nanotubes.

Creating Truly Flexible Circuits

Carbon nanotubes can be embedded within polymers, rubber-like substrates, or even fabrics, forming transparent, conductive films that are robust under extreme bending, stretching, or twisting. Unlike traditional metal wires or silicon chips—which break or lose conductivity when deformed—CNT-based materials retain their integrity even after thousands of flex cycles.

- Example: The University of Tokyo’s research team integrated CNT conductors into thin, flexible patches that continuously monitor patients’ heartbeat and muscle activity, transmitting real-time data wirelessly.

Smart Textiles and Beyond

CNT-laced fibers are being woven directly into clothing to measure movement, respiration, or temperature. Companies like Cambridge-based Xefro have commercialized heated garments using CNT technology, boasting faster, more efficient performance than standard heating elements.

Enhanced Foldable Displays

CNT networks also facilitate the development of thin, foldable touchscreens. By replacing indium tin oxide (ITO)—the standard transparent conductor, which is brittle and expensive—with CNT films, manufacturers are now prototyping tablets and phones that can be folded like newspapers, potentially revolutionizing portable electronics.

Energy Storage and Supercapacitors

Modern gadgets cry out for longer battery life and faster charging. Here too, carbon nanotubes are changing the game, both inside batteries and as the basis for new classes of 'supercapacitors.'

Upgrading Lithium-Ion Batteries

CNTs act as high-performance additives in electrodes by:

- Providing a highly conductive network, reducing resistance, and boosting charge/discharge rates.

- Preventing the formation of damaging dendrites in lithium-metal batteries.

- Increasing structural resilience during repeated charging cycles.

In 2019, researchers at the Massachusetts Institute of Technology (MIT) demonstrated lithium-ion batteries with CNT-reinforced anodes that not only charged much faster but survived over 10,000 cycles—25 times longer than ordinary batteries.

Supercharging Supercapacitors

Supercapacitors can deliver energy in bursts—crucial for applications like regenerative braking or flash photography. CNTs’ vast surface areas (due to their nano-scale tube structure) and superb conductivity enable storing and releasing large and rapid energy bursts. Companies such as Skeleton Technologies are scaling up production of CNT-based electrodes for automotive and industrial power systems, promising weight savings and durability compared to legacy materials.

Transparent Conductors for Advanced Displays

Touchscreens, organic LEDs (OLEDs), and next-generation solar panels depend on transparent conductors to function. The go-to material, indium tin oxide (ITO), is brittle, costly, and suffers from diminishing indium reserves.

CNT Films—A Sustainable Alternative

Carbon nanotube films form meshes or networks that allow light through while conducting electricity efficiently—imperative for touch sensors or display pixels. CNT conductors are:

- Flexible and Durable: They survive bending, folding, and even minor impacts without losing performance.

- Earth-Abundant: Unlike ITO, CNTs rely on carbon, one of Earth’s most plentiful elements.

- Easily Integrated: They can be sprayed, printed, or even inkjet-deposited onto large, curving surfaces—enabling unique display shapes and applications.

Major display manufacturers, including LG and Samsung, have showcased prototypes using CNT-based touch layers, demonstrating similar brightness and touch responsiveness but with greater flexibility than traditional tech.

Next-Generation Sensors and Diagnostic Devices

Imagine a smartphone case that instantly detects air pollution or a hospital patch that diagnoses infection from a single drop of sweat. Carbon nanotubes, with their immense surface area and sensitivity, are turning these into practical realities.

Ultra-Sensitive Biosensing

Functionalizing (adding chemical groups to) the surfaces of CNTs allows them to detect single molecules of toxins, pathogens, or biomarkers.

- Case in Point: The University of California, Berkeley’s research team developed CNT-based biosensors that could detect trace levels of cancer biomarkers in blood—far earlier than traditional techniques.

Paving the Way for Miniaturized Chemical Sensors

CNT-based sensors are extremely compact, consume minimal power, and respond quickly. Their self-assembly into tiny wires and pads opens doors for embedded detection in wearables, environmental monitors, or food packaging for spoilage identification.

Medical and Environmental Applications

Advanced breathalyzer devices using CNT sensors can distinguish hundreds of volatile organic compounds, allowing early detection of lung diseases or environmental toxins in real-time. As their cost drops, such sensors could be integrated into home health and IoT platforms worldwide.

High-Speed Data Transmission and Interconnects

While we've focused on the brain of electronics—transistors—the nervous system (the interconnects or wiring that ferry signals and power) is also being transformed by carbon nanotubes. Their ultra-high conductivity and resilience make them ideal for next-generation data links.

Beyond Traditional Copper Wires

Copper, the usual material for on-chip wires and global data cables, faces size and speed limitations, particularly as microprocessors scale down or data rates increase.

- CNT Bundles as Wires: Their ballistic electron transport supports breakneck speeds with little heat loss.

- Electromigration Resistance: Copper wires degrade over time as electrons physically 'push' atoms out of place (electromigration). CNTs, tied with strong atomic bonds, are immune to this effect, yielding far longer lifespans.

Data Centers and Internet Infrastructure

Companies like Nantero are developing CNT-based memory and interconnect solutions for high-performance servers and routers. These are already demonstrating lower energy losses and faster data transmission, pointing the way for future upgrades in data-intensive sectors.

Challenges and Opportunities Ahead

Despite immense promise, integrating carbon nanotubes into mainstream electronics is not without obstacles:

- Purity and Selectivity: Naturally grown CNTs are a mix of metallic and semiconducting types. Chemical and physical separation, while advancing, need further scalability.

- Alignment and Placement: Positioning trillions of nanotubes in the correct location and orientation remains a feat—but with breakthroughs in DNA scaffolding, electric fields, and solution-phase alignment, mass production is increasingly practical.

- Cost and Volume: Past high price tags for producing high-purity CNTs are dropping rapidly, driven by innovations in chemical vapor deposition and roll-to-roll processing.

There’s a parallel to the early days of silicon: the difficulties are considerable, but the incentives are massive. As costs decrease and fabrication refines, CNT technology is set to penetrate not just high-end tech but everyday devices.

Unfolding the Future—Applications We Can Only Dream Of

Every era of electronics has a signature material: vacuum tubes, then solid-state semiconductors, later, nanoscale silicon. Carbon nanotubes are fast emerging as a keystone of the next generation, empowering possibilities far beyond today's cutting edge. Just a few predictions include:

- Quantum Computing: CNTs possess unique quantum properties—such as spin and valley degrees of freedom—that could one day prime them for quantum processors, underpinning fantastically powerful new computers.

- Bioelectronics: With their biocompatibility, CNTs are the 'wires' of bionic implants, brain-computer interfaces, or artificial retinas, turning science fiction into medicine.

- Environmental Revolution: From desalination membranes to high-efficiency solar panels, CNTs may facilitate a cleaner, more sustainable electronic age.

As researchers worldwide continue to unravel the secrets and perfect the methods for working with carbon nanotubes, one certainty emerges: their role in electronics is not just surprising—it’s transformative. The next time you tap a flexible screen, charge your device in minutes, or wear a smart shirt, take a moment to appreciate the silent, invisible marvels operating at the nanoscale, powering the ever-surprising march of electronic innovation.

Rate the Post

User Reviews

Other posts in Engineering & Technology

Popular Posts