Why Do Polymers Outperform Metals in Modern Manufacturing

16 min read Explores how polymers surpass metals in modern manufacturing due to weight, versatility, and advanced properties. (0 Reviews)

Why Do Polymers Outperform Metals in Modern Manufacturing?

In the evolving landscape of manufacturing, choosing the right material drives innovation. For decades, metals led the way: strong, reliable, and time-tested. Yet, in the past several decades, polymers—once considered mere substitutes—have surged ahead, making inroads across automotive, aerospace, consumer electronics, medical devices, and beyond. But why are polymers outperforming metals in so many modern manufacturing applications? The answer lies in a rich tapestry of material science, economic pressures, advances in processing, and demands for sustainability. Let's explore the multifaceted reasons polymers have taken center stage, examining specific advantages, examples, and future insights.

What Makes Polymers Unique?

At the heart of the polymer revolution is their distinct molecular structure. Polymers are large, chain-like molecules composed of repeating subunits—monomers. This structure results in remarkable flexibility, lightweight properties, chemical versatility, and, perhaps most importantly, the ability to custom-tailor characteristics during synthesis.

Metals vs. Polymers: Contrasting the Basics

- Metals: Primarily arranged in crystalline structures with metallic bonds, resulting in high density, conductivity, and malleability.

- Polymers: Composed of covalent bonds and often semi-crystalline or amorphous, giving rise to lower density, corrosion resistance, and customizable properties.

For example, polyethylene (PE) can be as bendable as a plastic bag or, with molecular tweaks, as rigid as a playground slide. Such versatility is tough for metals to replicate without intensive alloying and complex processing.

Lightweight Advantage: Fuel Efficiency and Ergonomics

One of polymers' most celebrated strengths is their low density. Let's look at how this trait is game-changing:

Automotive & Aerospace

Every kilo shaved off a car or aircraft translates to significant fuel savings and lower emissions. Polypropylene, polycarbonate, ABS, and composites like carbon-fiber-reinforced polymers (CFRPs) now replace metal in dashboards, bumpers, body panels, interior trims, ducting, and even more structural applications with advanced composites. For instance:

- Boeing 787 Dreamliner: About 50% of its weight comes from composite materials, largely polymer-based, contributing to a 20% improvement in fuel efficiency compared to its all-metallic predecessors.

- Ford F-150: Now includes extensive use of polymer composites in panels and trim, reducing overall vehicle weight.

Ergonomics in Consumer Goods

Lightweight polymer housings are found in power tools, laptops, smartphones, and medical devices, enabling longer battery life and easier portability without sacrificing durability.

Corrosion Resistance and Chemical Stability

Where metals rust, polymers endure. This fundamental distinction is pivotal across industries.

Chemical Processing Plants

Metal pipes corrode in aggressive chemical environments, necessitating expensive alloys or continuous maintenance. Assess the case of polyvinylidene fluoride (PVDF): It lines pipes and tanks that handle acids and solvents, remaining intact where stainless steel would pit and fail.

Marine & Outdoor Applications

- PVC decking outlasts wood and steel in marine piers because it doesn't rust, rot, or fade easily.

- Polymer coatings for offshore oil platforms shield sensitive metal components from seawater’s harsh, corrosive impact.

Such advantages substantially reduce ongoing maintenance, downtime, and replacement costs, allowing industries to operate more efficiently.

Design Versatility: Enabling Innovation

Imagine complex 3D shapes, detailed textures, embedded functionalities, or translucent casings—features difficult, costly, or sometimes impossible to realize with metals. Polymers excel in manufacturing design:

Injection Molding & Complex Shapes

Polymers can be melted and injected into highly precise molds. Automotive dashboards, appliance housings and tool enclosures rely on such complex, integrated designs that would be cost-prohibitive or technically challenging with traditional metals.

Customization & Functional Integration

With polymers, it’s possible to integrate features directly into components:

- Hinges, snap-fits, and living hinges in a single mold.

- Electrical insulation or EMI shielding embedded within enclosures.

- Colors, translucency, and textures applied during production.

Case in point: Modern laptop shells combine durability with aesthetics—all manufactured more readily with advanced thermoplastic resins.

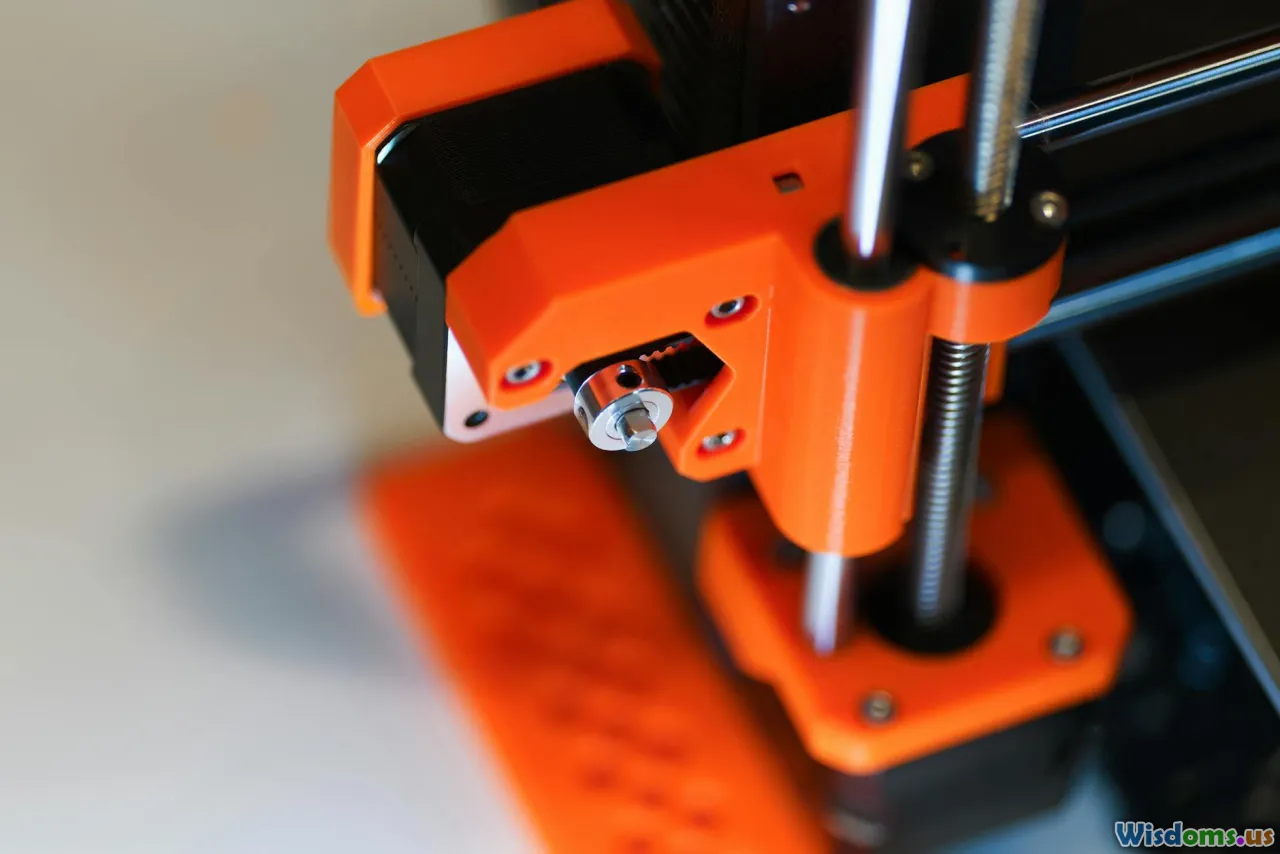

Additive Manufacturing (3D Printing)

Polymer powders and filaments drive widespread use of 3D printing, enabling prototyping and small-batch production not only faster but more economically than traditional metal fabrication. With advances in high-performance, fiber-reinforced polymers, even functional mechanical parts can be printed up to production standards.

Cost-Effectiveness: Material and Manufacturing Efficiency

Economics underpin every manufacturing decision. Polymers often win because:

- Lower Raw Material Costs: Many commodity plastics (e.g., polypropylene, polyethylene, PVC) are less expensive than most metals per unit.

- Efficient Processing: High-speed injection molding, extrusion, blow molding, or 3D printing lowers labor and cycle costs.

- Less Waste: Near-net-shape manufacturing minimizes scrap—the molding process uses almost the exact amount of material needed for each part, unlike processes such as subtractive machining of metals.

Example: Manufacturing complex automotive instrument panels via polymer injection molding can be done in seconds, with robots removing finished pieces ready for assembly, all at a fraction of the energy and timeline compared to multiple-step metal stamping, welding, and finishing.

Customization of Mechanical and Physical Properties

Rather than the one-size-fits-all approach of metallic alloys, polymers excel at customization.

Tuned for Performance

Polymers’ chemistry allows for the adjustment of:

- Flexibility

- Impact resistance

- Transparency

- Weatherability

- Fire resistance

- Electrical insulation/conductivity (by mixing in carbon, metals, or special additives)

Blending polymers and adding fillers—like glass or carbon fibers—can boost select properties beyond those of many metals. Polyamide 6,6 reinforced with 30% glass fiber can be as rigid as aluminum and, in some specifications, displays better fatigue performance under dynamic load.

Real-World Applications

- Electronics: Polycarbonate for phone screens, combining clarity and crack resistance.

- Medical Devices: PEEK polymer implants, strong enough for spinal or dental applications, but with a modulus closer to bone than titanium, improving patient comfort and healing.

Thermal and Electrical Insulation

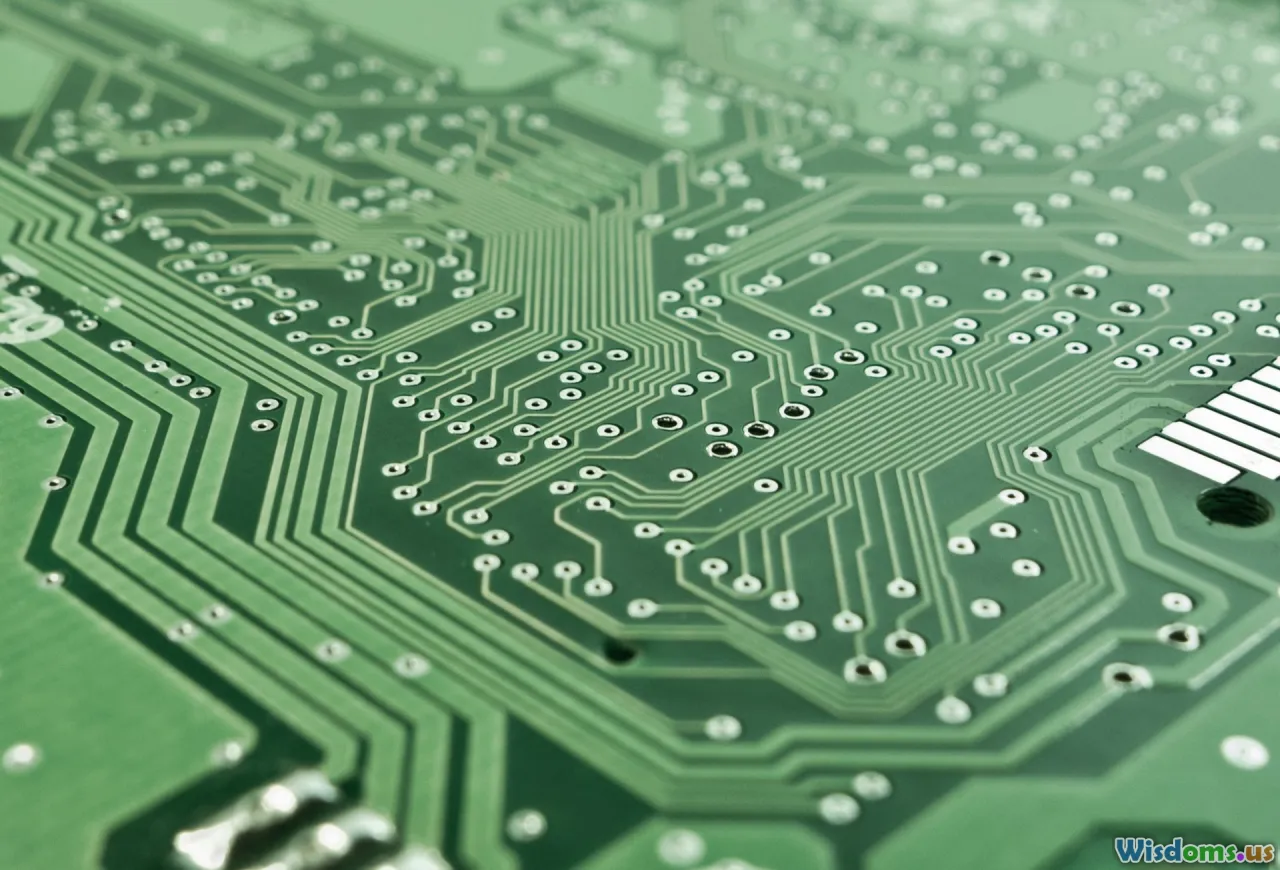

Few metals insulate like polymers. Modern equipment increasingly requires both electrical safety and lightweight solutions.

- Wire insulation: PVC, Teflon (PTFE), and other polymers coat almost all electrical wiring, from household cables to aerospace harnesses.

- Circuit boards: Epoxy-based laminates (FR4) underpin the structure of the world’s printed circuit boards, combining insulation, dimensional stability, and fire resistance.

Without polymers, neither modern data centers nor consumer gadgets could function safely or efficiently.

Sustainability and Environmental Benefits

Societal and environmental pressures are reshaping material choices. Polymers answer with lower production energy and emerging eco-options.

Energy Savings in Manufacture

Smelting and forming metals, especially aluminum and steel, are energy-intensive and major contributors to greenhouse gases. In contrast, processing most polymers requires far less heat, reducing a product’s carbon footprint considerably.

Advancements in Recycling and Biopolymers

- Closed-loop recycling: Polyethylene terephthalate (PET) used in bottles is recycled into new containers, fabrics, and automotive parts.

- Biodegradable options: Plant-based polylactic acid (PLA) is used in disposable dishes, packaging, and even medical implants.

- Recycled composites: Automotive makers like BMW and Ford increasingly incorporate recycled polymers into non-structural and structural car parts, underscoring environmental responsibility.

Challenges remain—especially around microplastics, end-of-life management, and consistent recycling streams—but continuous innovation keeps pushing polymer technology in greener directions.

Durability: Impact, Fatigue, and Life-Cycle Resilience

Some may question the durability of plastics compared to metals, but real-world performance tells a different story:

- Impact Resistance: Polycarbonate windows are virtually shatterproof, used in riot shields, airplane canopies, and premium eyewear.

- Fatigue Life: Glass-fiber reinforced nylons in automotive gearing handle repeated cycles better than powder metal alternatives, offering longer maintenance intervals.

- Weatherability & UV Stability: Engineering polymers can be stabilized to withstand decades outdoors with minimal color or strength loss – think stadium seats or wind turbine blades.

Safety and Regulatory Compliance

Polymers can be formulated to comply with the most demanding safety and regulatory standards.

- Food & Medical Applications: Polymers like polypropylene and medical-grade silicones are biocompatible, sterilizable, and free from harmful plasticizers—preferred over metals that may corrode or leach ions.

- Fire Performance: Flame-retardant plastics inhibit ignition and suppress smoke, vital for public transport interiors, electronic housings, and building products.

- Non-Toxicity: Infant toys, water bottles (BPA-free), and even spacecraft interiors leverage certified polymers for health and safety.

Polymers in High-Performance Applications: The Ultimate Test

It's not just in mass-market uses—polymers are spearheading the most demanding, cutting-edge challenges.

- Spacecraft: Polyimide films (Kapton) survive both the searing sun and relentless cold of space on satellites and telescopes.

- Aerospace Tackles Metal’s Limits: Advanced CFRP components replace aluminum and titanium for primary load-bearing structures, offering a unique combination of stiffness, fatigue resistance, and weight savings.

- Formula 1 and Racing: High-performance polymer composites form critical bodywork and safety elements, showing superior performance under stress, impact, and extreme thermal conditions.

Navigating Polymers' Limitations—And Why They Still Prevail

No material is perfect. Skeptics often raise points about polymers:

- Metals generally maintain superior strength and modulus at high temperatures due to inherent molecular bonds.

- Some polymers creep or deform under load over time, and many are more easily scratched than metal counterparts.

- Solvent sensitivity (some degrade in specific chemicals) and vulnerability to UV can limit certain applications.

How are manufacturers overcoming these?

- Developing high-temperature polyimides, PEEK, and PPSU—allowing complex parts to operate above 200°C.

- Additives: Incorporating UV stabilizers, flame retardants, and nano-reinforcements to enhance properties beyond metal realms.

- Careful design: Engineering polymers are deployed strategically—exploiting their strengths in combinations and composites, often paired with metals where synergy is beneficial.

The Future: Polymers Catalyzing the Next Manufacturing Revolution

Material science stands on the threshold of a new era. Self-healing polymers, conductive plastics for flexible electronics, and composites engineered at the nanoscale forecast a future where metal's dominance further erodes. As sustainability imperatives tighten and digital manufacturing transforms supply chains, polymers' tunability, processing efficiency, and environmental adaptability will only grow in relevance.

From lightening the weight of vehicles and planes, enabling sleek tech gadgets, protecting the planet’s resources, to delivering life-saving medical care, polymers have indisputably earned their place as the material cornerstone of modern manufacturing.

Choosing polymers is more than a design decision—it’s a strategic move propelling innovation and shaping the future of how we make, use, and dream about products in a rapidly changing world.

Rate the Post

User Reviews

Other posts in Chemistry & Chemical Engineering

Popular Posts