Tracking Factory Power Consumption With Advanced IoT Sensors

33 min read How advanced IoT sensors track factory power consumption, improve visibility, cut energy costs, and streamline compliance with ISO 50001 using edge analytics, non-intrusive load monitoring, and real-time dashboards. (0 Reviews)

Factories don’t just consume electricity; they perform a complex choreography of power conversion, transient spikes, harmonics, idle loads, and demand peaks. Without clear visibility, energy becomes an opaque line on the P&L—expensive, volatile, and often higher than necessary. Advanced IoT sensors make energy use observable at the circuit, machine, and even subcomponent level, turning guesses into data-driven decisions. With the right architecture, you can curb waste, prevent downtime, and translate kilowatts into KPIs everyone understands—from operations and maintenance to finance and sustainability.

Why Real-Time Power Tracking Matters

Electricity remains one of the top three operating costs for many manufacturers, and it’s becoming more volatile. Global industrial electricity prices have fluctuated significantly over the past decade, and many utilities have introduced time-of-use tariffs, critical peak pricing, and demand charges that penalize short bursts of high power. For example, a 15-minute demand spike can contribute to as much as 30–50% of the monthly bill due to demand charges, even if total energy use is modest. In parallel, corporate carbon targets and environmental standards (such as ISO 50001 energy management systems) require auditable energy data.

Real-time tracking yields tangible benefits:

- Reduced energy intensity: Plants that implement submetering and real-time analytics often achieve 10–25% energy reductions within the first year. Savings come from eliminating idle loads, optimizing schedules, and tuning power factor.

- Lower demand charges: Smoothing peaks through sequencing, storage, or load shedding can cut demand charges by 10–20% without affecting output.

- Better asset reliability: Power anomalies (voltage sags, THD spikes, or unbalanced phases) accelerate wear. Early detection prevents trips and failures.

- Quality improvements: Process deviations sometimes show up first as power signatures—e.g., a heater struggling to maintain setpoint due to scaling will draw higher current, correlating with product defects.

- Data for reporting and incentives: Many utilities offer rebates for submetering, power factor correction, and VFDs. Reliable measurements make it easier to secure incentives and validate results.

Short story, real-time monitoring shifts energy from a fixed cost to a controllable variable. You unlock not just savings but also predictable production.

What Counts as an “Advanced” IoT Power Sensor

Not all meters are equal. Advanced IoT power monitoring systems combine high-quality sensors with edge processing, secure connectivity, and flexible data models.

Key features to look for:

- High accuracy: Class 0.5S or better (per IEC 62053-22 for active energy). For submetering at the panel or feeder, Class 1 may be sufficient, but for cost allocation and continuous improvement, push toward 0.5S.

- Waveform capture and high sampling rate: Devices that capture at 128 samples per cycle or higher can detect transients and harmonics. If your concern is power quality, look for support for IEEE 1459 parameters and EN 50160 compliance reporting.

- Multi-parameter measurement: Beyond kWh and kW, track PF (displacement and true), THD (voltage and current), individual harmonics (up to the 50th or higher), unbalance, and demand over custom intervals.

- Edge analytics: Onboard algorithms for power factor alarms, anomaly detection, or NILM-like disaggregation reduce bandwidth and latency.

- Flexible I/O: CTs (current transformers), Rogowski coils for high currents, voltage taps, pulse inputs from legacy meters, and digital inputs for status.

- Communications: Native support for Modbus TCP/RTU, MQTT (with Sparkplug B), OPC UA, and REST. Time sync via NTP or PTP is essential for aligning events across assets.

- Security: TLS, X.509 certificates, secure boot, signed firmware, and fine-grained role-based access.

A modern sensor is more than a meter—it’s a compact, ruggedized data appliance that speaks the language of industrial IT and OT.

Choosing the Right Sensor for Each Job

No single sensor addresses every use case. Use a portfolio approach and match sensor types to current ranges, accuracy needs, safety constraints, and install effort.

-

Split-core CTs:

- Best for: Retrofitting without disconnecting conductors. Typical ranges up to 1000 A.

- Pros: Fast to install, safe when closed, suitable for permanent submetering.

- Cons: Slightly lower accuracy than solid-core; must ensure correct orientation and secure closure.

-

Solid-core CTs (measuring or metering grade):

- Best for: New installations or when conductors can be disconnected briefly.

- Pros: High accuracy, low phase error, stable over time.

- Cons: Intrusive to install, may require downtime.

-

Rogowski coils:

- Best for: High-current applications (up to tens of kA), irregular busbars, or tight spaces.

- Pros: Flexible, safe (open-circuit secondary is not hazardous), wide bandwidth for transient capture.

- Cons: Requires integrator; sensitive to placement and calibration; accuracy can be lower than CTs for low currents.

-

Hall-effect sensors:

- Best for: DC and AC mixed environments (e.g., electroplating, battery systems, large drives).

- Pros: Measures DC; galvanic isolation; good dynamic response.

- Cons: Temperature drift and offset; select industrial-grade devices.

-

Smart power meters (panel or feeder meters):

- Best for: Permanent installation at switchboards, MCCs, and main incomers.

- Pros: Multiparameter analytics, alarming, event logs, demand calculations; often support Class 0.2–0.5.

- Cons: Higher cost; may require panel modifications and voltage taps.

-

Inline branch-circuit meters:

- Best for: Machine-level accountability, OEM skids, and cost allocation.

- Pros: Fine granularity; correlates machine events with power signatures.

- Cons: Many points to maintain; ensure consistent naming and tagging.

If unsure, run a pilot with a few of each type. Evaluate install time, data integrity, and the types of insights each sensor provides in your environment.

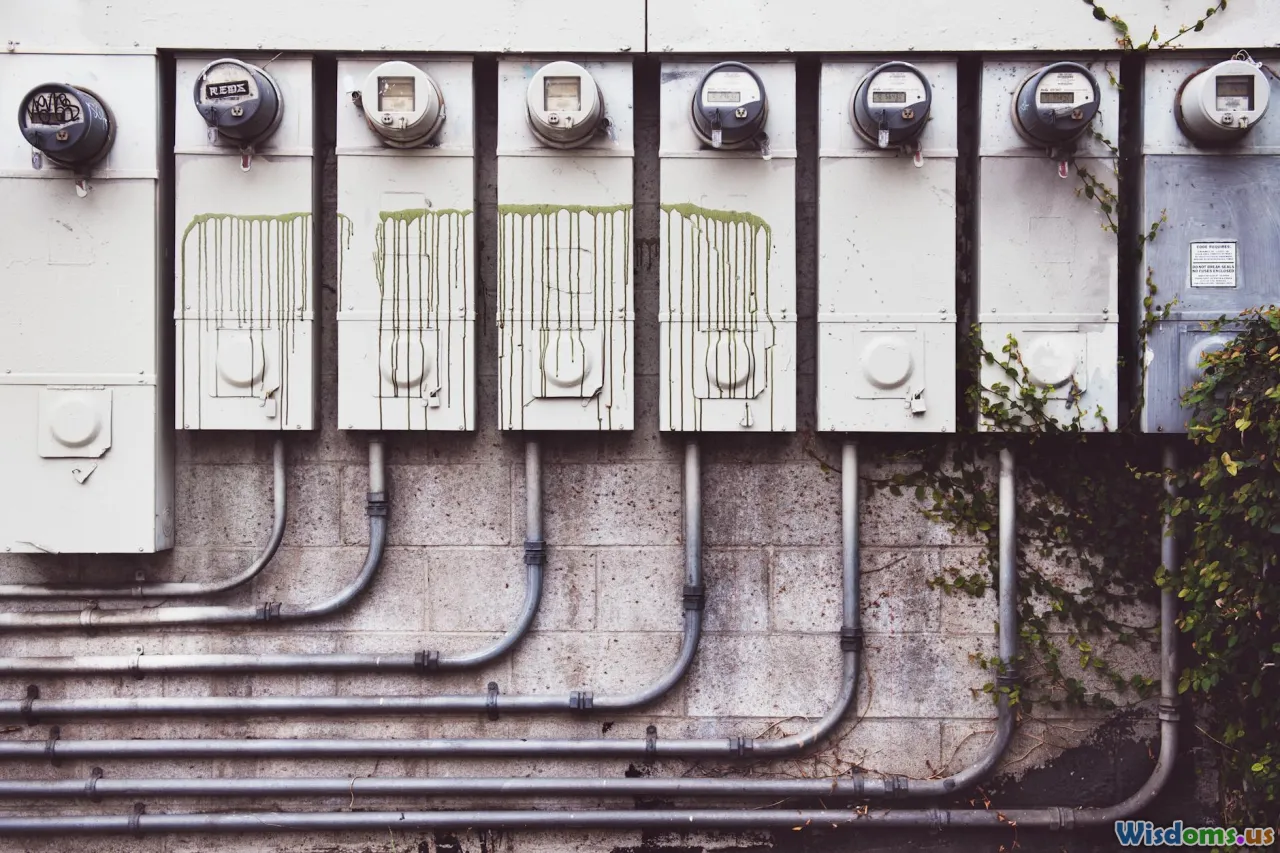

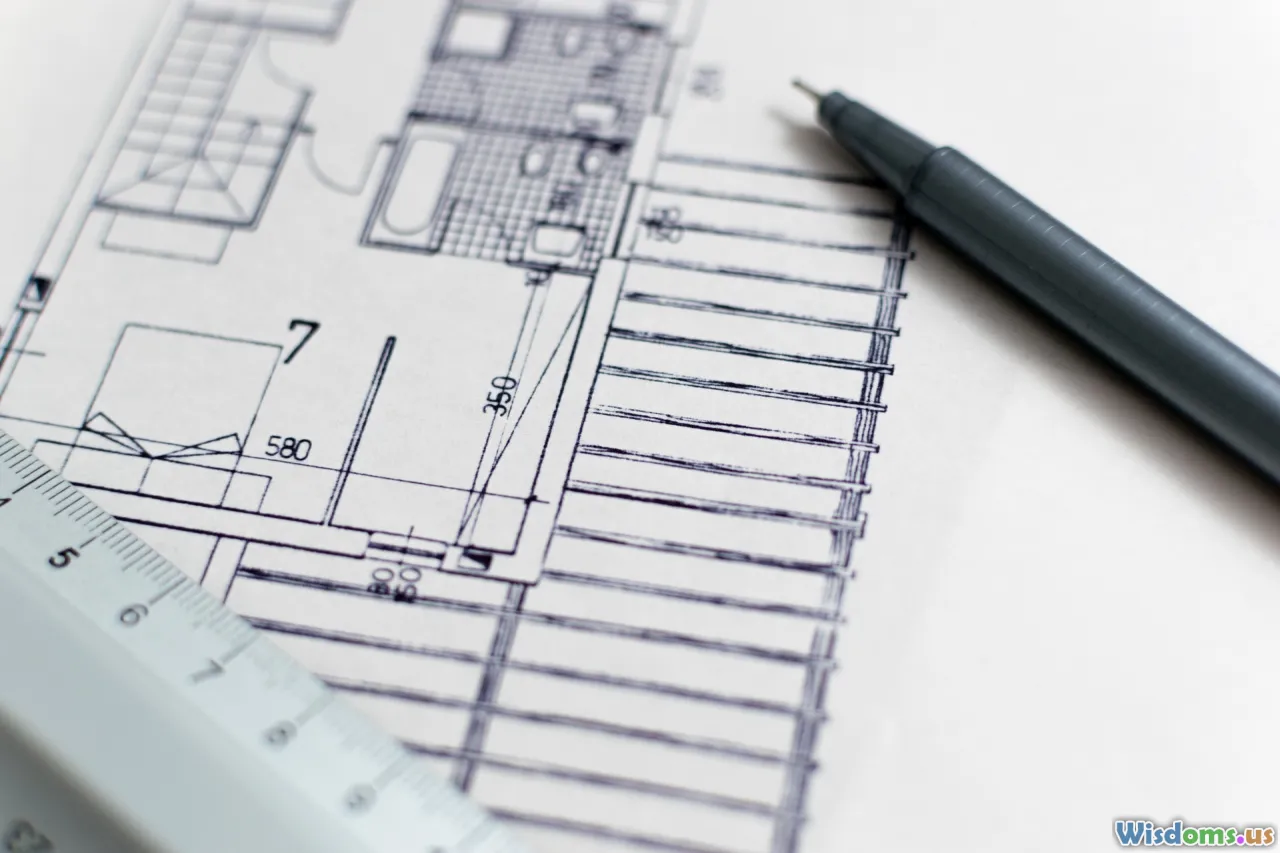

Plan the Rollout Before Touching a Wire

Successful deployments start on paper. A day spent planning can save weeks of rework.

- Define objectives and KPIs:

- What do you want to reduce or improve—kWh, demand peaks, PF penalties, scrap, downtime?

- Translate goals into KPIs like kWh/unit, kW per line, PF > 0.95, V THD < 5% at the point of common coupling.

- Map your electrical distribution:

- Gather single-line diagrams. If they’re outdated, update them during a site walk.

- Identify main incomers, transformers, switchboards, MCCs, and major feeders.

- Prioritize circuits: start with 20% of feeders that represent 80% of load.

- Select measurement points:

- Main meter for baseline versus utility bill reconciliation.

- Feeder meters for large areas (e.g., press shop, paint line, compressed air room).

- Machine-level meters for energy-critical assets (e.g., ovens, chillers, compressors, injection molding machines).

- Balance phases where possible; measure neutral where harmonics are a concern.

- Choose sensor classes and ranges:

- Ensure CT ratios match expected currents with headroom (e.g., 800 A bus with 1000:5 CTs).

- Accuracy class: 0.5S for cost allocation; Class 1 may suffice for trend-only.

- Plan communications and data routes:

- Decide on field protocols (Modbus RTU), uplinks (MQTT over TLS), and gateways.

- Confirm switch capacity, VLANs, and firewall rules for segmented OT networks.

- Safety and compliance plan:

- NFPA 70E procedures; LOTO; arc flash boundaries and PPE.

- Use Rogowski coils when panels can’t be de-energized.

- Documentation and labeling:

- Label panels, circuits, CT polarities, device IDs, and network addresses.

- Adopt a naming convention now to avoid chaos later (e.g., Site_Area_Panel_Circuit_Phase).

Write a simple measurement plan document: scope, device list, diagrams, install procedures, data validation steps, and acceptance criteria.

A Step-by-Step Implementation Blueprint

Follow a phased approach to reduce risk and build confidence.

Phase 1: Pilot

- Select one area with diverse loads (e.g., compressor room plus a production line).

- Install 10–20 measurement points: main feeder, compressor feeds, oven, chiller, conveyor drives.

- Use a gateway that supports MQTT Sparkplug B and OPC UA. Configure secure certificates.

- Validate data with handheld meters or clamp meters; reconcile with main utility meter over a week.

Phase 2: Harden and scale

- Standardize on a device list: specific CT types, models of meters, and gateways.

- Implement time synchronization (NTP across OT VLAN; PTP if you need sub-millisecond alignment for transient correlation).

- Build dashboards: daily energy per line, peak demand heatmap, PF by area, anomalies flagged.

Phase 3: Integrate and automate

- Trigger alerts when kW exceeds thresholds or PF drops below 0.9.

- Enable demand control: stagger machine starts; delay noncritical loads during a peak window.

- Feed MES with kWh per batch and per job; feed CMMS with abnormal power signatures to trigger inspections.

Installation tips that save headaches:

- Always short CT secondaries before disconnecting from a meter; never open-circuit measuring CTs.

- Verify phase sequence (A-B-C) and orientation. Wrong polarity yields negative power readings or PF > 1 illusions.

- Document burden settings for Rogowski integrators and confirm they match meter requirements.

- After installation, perform a “light-load test” and a “full-load test” to ensure readings align within expected uncertainty.

Data Modeling and Tagging That Scales

Measurement without context is noise. Robust metadata makes analytics reusable and integrations painless.

- Hierarchical modeling: Follow ISA-95 levels and areas/lines/cells/equipment hierarchy. For example: Plant01.AreaA.Line3.MCC2.Feeder05.

- Common tag schema: name, description, asset ID, feeder, voltage level, CT ratio, phase, meter accuracy class, commissioning date.

- Units & transforms: Store raw and engineering units. Apply scaling consistently (e.g., 5 A secondary = CT_ratio × 5 A).

- Semantic layers: Use OPC UA information models or Sparkplug B templates to encode device types and metrics in a standardized way.

- Versioning: When you recalibrate or change a CT, update the tag metadata and maintain an audit trail.

- Event alignment: Enforce a synchronized timestamp standard (UTC with NTP/PTP). Store offset and jitter metrics to detect clock drift.

Good tagging turns “Feeder05 kW” into “Plant01.AreaA.Line3 Oven1 Heater kW,” which unlocks traceability and accurate cost allocation.

Analytics That Deliver Savings

Raw data becomes savings when you convert it into actionable insights. Here are analyses that consistently drive ROI:

-

Load profile analysis:

- Compare weekday vs weekend baselines. Idle loads often persist 24/7. A compressor room that draws 40 kW overnight is a red flag for leaks or control inefficiency.

- Identify short, sharp peaks tied to shift starts or coordinated machine starts. Sequencing can cut those peaks.

-

Power factor improvement:

- Monitor PF by area and time of day. Low PF triggers higher current and sometimes penalties. Correct with capacitor banks or active filters, but start by identifying the loads causing poor PF (large induction motors, welders) and consider VFDs where appropriate.

-

Harmonics and power quality (PQ):

- Track voltage THD and current THD. As a guideline, keeping voltage THD below about 5% at the point of common coupling aligns with common industry targets derived from standards like IEEE 519. High THD can cause transformer heating and nuisance trips. Active harmonic filters or 12/18-pulse drives may be warranted if specific harmonics dominate.

-

Anomaly detection on signatures:

- Implement thresholds and z-score alerts on kW, current unbalance, and THD. Add simple machine learning to flag deviations from normal patterns under similar production conditions.

- Example: A molding machine’s clamp motor normally peaks at 30 kW for 2 seconds each cycle. An increase to 35 kW with longer duration may indicate mechanical binding or hydraulic issues.

-

Non-Intrusive Load Monitoring (NILM) at the panel level:

- Disaggregate composite signals to infer which machines are running and how much they consume. Even basic disaggregation on edge devices (using step changes and harmonics) can distinguish compressors, heaters, and drives.

-

KPI benchmarking:

- kWh per batch, kWh per unit, kWh per hour of runtime, kW per square meter of conditioned area.

- Normalize energy to production (good units, not just total units) to avoid hiding scrap behind “efficiency.”

-

Demand charge control:

- Forecast the 15-minute demand window using rolling averages. Pre-cool or pre-heat processes when energy is cheap; defer noncritical loads when approaching a peak.

These analytics don’t require a data science department on day one. Start with clear thresholds and daily reviews; then layer advanced methods.

Use Cases Across Departments

-

Operations:

- Sequence equipment startups to avoid peaks.

- Tune oven soak times and line speeds to reduce wasted heat.

-

Maintenance:

- Monitor current unbalance on three-phase motors; >2–3% unbalance can overheat windings.

- Flag rising current in pumps as an indicator of bearing wear or impeller fouling.

-

Quality:

- Correlate power draw variability with defect rates. Heater irregularities or unstable drive loads often predate quality drifts.

-

Energy and sustainability:

- Track Scope 2 emissions with time-based grid factors. Produce hourly emissions reports by line.

-

Finance:

- Allocate energy costs by product family or work center. Validate vendor performance for energy-intensive outsourced processes.

-

EHS:

- Detect abnormal heat from panels indirectly via higher copper losses or THD spikes; prioritize inspections.

When every team sees their role in the energy picture, accountability and improvement accelerate.

Data Quality, Calibration, and Uncertainty

Trustworthy numbers require disciplined metrology.

-

Accuracy classes and uncertainty budgets:

- Add up sensor accuracy (CT class), meter accuracy, and calibration drift. A typical setup might have a combined uncertainty of 0.6–1.0% for kWh at the feeder level.

-

Calibration schedule:

- Calibrate meters every 2–3 years or per manufacturer guidance. Compare with a portable reference standard annually.

-

Drift and temperature effects:

- Document the ambient range. Rogowski coils and Hall sensors can drift with temperature; compensate or specify appropriate devices.

-

Validation tests:

- Perform an in-situ cross-check: sum of feeder kWh should align with main meter (minus transformer and distribution losses). Investigate discrepancies >3–5%.

-

Sampling and aggregation:

- Choose meaningful intervals: 1-second to 1-minute for operations; 15-minute for demand; hourly/daily for reports. Avoid aliasing by ensuring sampling is high enough for the phenomena you care about.

-

Data completeness:

- Monitor for gaps. Track data latency and packet loss. Implement store-and-forward at gateways to handle network outages.

Put QA gates in your data pipeline. Energy data that’s off by a few percent can mislead decisions and undercut credibility.

Cybersecurity and Safety in the Same Conversation

Power data lives at the intersection of IT and high-energy equipment. Treat both with rigor.

-

Cybersecurity (IEC 62443-aligned):

- Network segmentation: Isolate OT networks, use firewalls, and restrict northbound traffic.

- Identity and encryption: TLS 1.2+ with device certificates. Rotate certificates and credentials; use a PKI.

- Least privilege: Limit write access to meters; disable unnecessary services and ports.

- Patch and vulnerability management: Track firmware versions; apply signed updates during planned windows.

-

Electrical safety:

- Follow NFPA 70E and local codes. Perform LOTO prior to installation; assess arc flash boundaries.

- Never open-circuit CT secondaries; use shorting blocks and test switches.

- Prefer Rogowski coils for temporary measurements when de-energization is impractical.

A secure and safe system protects people, equipment, and the integrity of your program.

Edge vs. Cloud: Architect for Latency, Bandwidth, and Resilience

-

Edge strengths:

- Millisecond latency for real-time control (e.g., peak shaving by pausing noncritical loads).

- Local buffering during WAN outages; store-and-forward ensures no data loss.

- On-device analytics reduce bandwidth: transmit kW, PF, and events instead of raw waveforms.

-

Cloud strengths:

- Long-term storage and trend analysis.

- Fleet-wide learning, benchmarking across plants.

- Heavy compute for NILM, forecasting, and optimization.

-

Hybrid patterns:

- Edge computes features and alarms; cloud stores history and runs periodic model training. Models are then deployed back to gateways.

- Use MQTT Sparkplug B for stateful, birth/death certificates and standardized payloads; use OPC UA for rich information models and secure, vendor-neutral interoperability.

Design the pipeline so that an internet outage doesn’t stop production or blind operators.

ROI Model You Can Defend

A credible financial model makes funding straightforward. Here’s a sample calculation for a mid-sized factory.

Assumptions:

- Annual consumption: 2.0 GWh

- Average energy price: $0.12/kWh

- Monthly peak demand: 1,000 kW

- Demand charge: $15/kW-month

- Project scope: 75 sensors/meters across main, feeders, and key machines

- Capex: $70,000 (hardware and installation)

- Software and integration (year 1): $20,000

- Ongoing annual software/support: $12,000

Baseline annual energy cost:

- Energy: 2,000,000 kWh × $0.12 = $240,000

- Demand: 1,000 kW × $15 × 12 months = $180,000

- Total baseline = $420,000

Conservative benefits after 12 months:

- 8% reduction in kWh via idle load elimination and scheduling = 160,000 kWh × $0.12 = $19,200

- 10% peak demand reduction (through sequencing and alerts) = 100 kW × $15 × 12 = $18,000

- Additional PF penalty elimination or reduced maintenance (conservative) = $7,500

- Total annual benefit ≈ $44,700

Investment and payback:

- Year 1 total cost: $70,000 + $20,000 + $12,000 = $102,000

- Net Year 1 cash impact: $44,700 savings − $102,000 = −$57,300

- Year 2 onward: $44,700 − $12,000 = $32,700 annual net savings

That’s a 3.1-year simple payback on conservative assumptions. Many plants achieve >15% energy reduction and larger peak cuts, which can halve the payback. Include utility incentives for submeters, capacitors, or VFD upgrades to further improve the numbers.

A Practical Case Study: 90 Days to Insight

A discrete manufacturing plant running two shifts installed advanced meters on the main incomer, three feeder panels, and six critical machines: two air compressors, an annealing oven, a chiller, and two large CNCs. Total of 24 sensors including panel meters, split-core CTs, and Rogowski coils.

Week 1–2: Baseline and anomalies

- The overnight baseline was 85 kW with no production. Analysis revealed both compressors auto-cycling due to leakage and controls set to redundant operation even at low demand. The oven’s insulation loss also kept draw at 12 kW.

- THD on one feeder hit 9% during heavy welding; a legacy rectifier contributed strong 5th and 7th harmonics.

Actions:

- Compressor controls reconfigured: one lead, one lag with a wider pressure band; scheduled nightly auto-shutdowns.

- Maintenance fixed eight compressed air leaks; oven door seals replaced.

Week 3–6: Demand smoothing

- Dashboards flagged 250 kW spikes at 6:55 a.m. as all equipment started simultaneously.

- A simple rule in the edge gateway staggered startups over 8 minutes and delayed noncritical conveyors until the annealing oven stabilized.

Results:

- Overnight baseline fell from 85 kW to 46 kW.

- Morning peaks dropped by 18%, lowering the monthly demand charge baseline.

- THD brought down to 5.5% by shifting welding cycles and adding a small active filter shared across two bays.

Week 7–12: Production normalization and cost allocation

- Engineering correlated kWh per batch on the oven with scrap rates; a drift in heat profile coincided with higher pull.

- A failing circulation fan increased current by 15% over two weeks; an alert triggered a bearing change before a costly failure.

Three-month outcome:

- Energy use reduced by 9.4% without any capital-intensive retrofits.

- Estimated annualized savings: ~$38,000 at local tariff rates.

- The team budgeted a VFD retrofit for the chiller pump and a larger harmonic filter for the welding feeder, with calculated paybacks under 24 months.

The case shows how visibility, not guesswork, catalyzes cross-functional wins.

Integrating With SCADA, MES, CMMS, and ERP

A monitoring island has limited value. Integrate energy data into systems people already use.

-

SCADA/HMI:

- Live kW, PF, and alarms per line. Use OPC UA or native drivers. Keep write permissions off by default to meters.

-

MES:

- Attach kWh to batches, jobs, and SKUs. Normalize energy per good unit, not total output, to avoid masking scrap costs.

-

CMMS:

- Create work orders from power anomalies (rising motor current, PF dips, unbalance). Store power signatures as attachments for root cause analysis.

-

ERP/Finance:

- Cost centers and product costing receive monthly allocations based on measured kWh per line.

-

Data lake/analytics platform:

- Store downsampled features (1-second to 1-minute) and daily aggregates. Avoid ingesting raw waveforms unless you have a use case and storage budget.

Design for open standards (OPC UA, MQTT Sparkplug B) to avoid lock-in and reduce integration friction.

Practical Tips From the Field

- Label everything. Future you will thank you. Include phase orientation and CT ratios on physical labels and in software.

- Take photos of every install. Store them with asset records to speed troubleshooting.

- Start shift-start tests: look at kW and PF during the first 15 minutes of each shift. This is where most peaks and surprises live.

- Establish “quiet hours” baselines: weekends and nights reveal leaks, vampire loads, and control mistakes.

- Normalize energy use by weather (for HVAC and chiller loads) and by production volume (for lines). Keep these factors front-and-center in dashboards.

- Don’t chase the last 0.2% of accuracy if you’re leaving 10% savings on the table. Focus on high-impact findings first.

- Keep spares: CTs, Rogowski integrators, fuses, test switches, and at least one spare panel meter.

- Document firmware versions and config snapshots; treat meters like PLCs.

Small, disciplined habits prevent common pitfalls and keep your system trustworthy.

Aligning With Standards and Incentives

- ISO 50001: Use your meter data to drive the Plan-Do-Check-Act cycle, set energy performance indicators (EnPIs), and document improvements.

- Utilities and regulators: Many utilities offer incentives for submetering, VFDs, capacitor banks, and power quality improvements. Your advanced sensors provide the data needed to qualify and to verify savings.

- Power quality norms: Track parameters relevant to IEEE 519-style guidance at the point of common coupling. Share summarized reports with your utility if you operate large nonlinear loads.

- Internal compliance: Build periodic reviews into your management system—monthly energy meetings with dashboards, quarterly audits of accuracy and data completeness.

Standards and incentives turn your technical program into an organizational habit with lasting support.

The Road Ahead: Smarter Grids, Smarter Plants

- Edge AI: Expect more NILM and anomaly detection on the gateway, with federated learning across plants.

- Time-Sensitive Networking (TSN): Deterministic Ethernet combined with OPC UA PubSub will simplify reliable data flow from sensors to applications.

- Digital twins: Energy twins of lines and utilities (compressed air, chilled water) will simulate demand response strategies before deploying them.

- Carbon-aware scheduling: As grids publish granular emissions intensity by hour, plants will optimize not only for cost but for carbon, shifting flexible loads accordingly.

- Integrated electrification: As you add EV charging, heat pumps, and onsite solar/storage, advanced sensors become the bedrock for orchestration and safe interconnection.

Factories that see electricity as a controllable variable—and measure it with discipline—gain an advantage that compounds. Advanced IoT sensors bring precision to a domain once ruled by averages and assumptions. Start small, plan well, instrument the right points, and let the data guide you. In a few months, “power consumption” stops being a line item and becomes a lever for efficiency, reliability, and resilience.

Technology Predictive Maintenance edge computing Internet of Things (IoT) Industrial IoT Energy Management Smart Factory Manufacturing Analytics IoT energy monitoring advanced metering infrastructure non-intrusive load monitoring (NILM) OPC UA Modbus RTU/TCP power quality monitoring demand charge reduction ISO 50001 compliance real-time dashboards data lake integration

Rate the Post

User Reviews

Other posts in Internet of Things (IoT)

Popular Posts