Inside a Modular Building Factory Step by Step Guide

17 min read Discover each stage in a modular building factory from design to installation, including innovative processes and quality systems shaping modern construction. (0 Reviews)

Inside a Modular Building Factory: Step by Step Guide

Step off the busy street and into the humming world of a modular building factory—where construction meets precision engineering, and entire buildings take shape faster and smarter than ever before. As interest in offsite construction surges globally, modular factories have become the hidden engines powering schools, hospitals, apartments, and office blocks. In this exclusive step-by-step guide, you’ll discover how raw materials become beautifully finished spaces, ready to be delivered anywhere.

Setting the Stage: Where Innovation Meets Demand

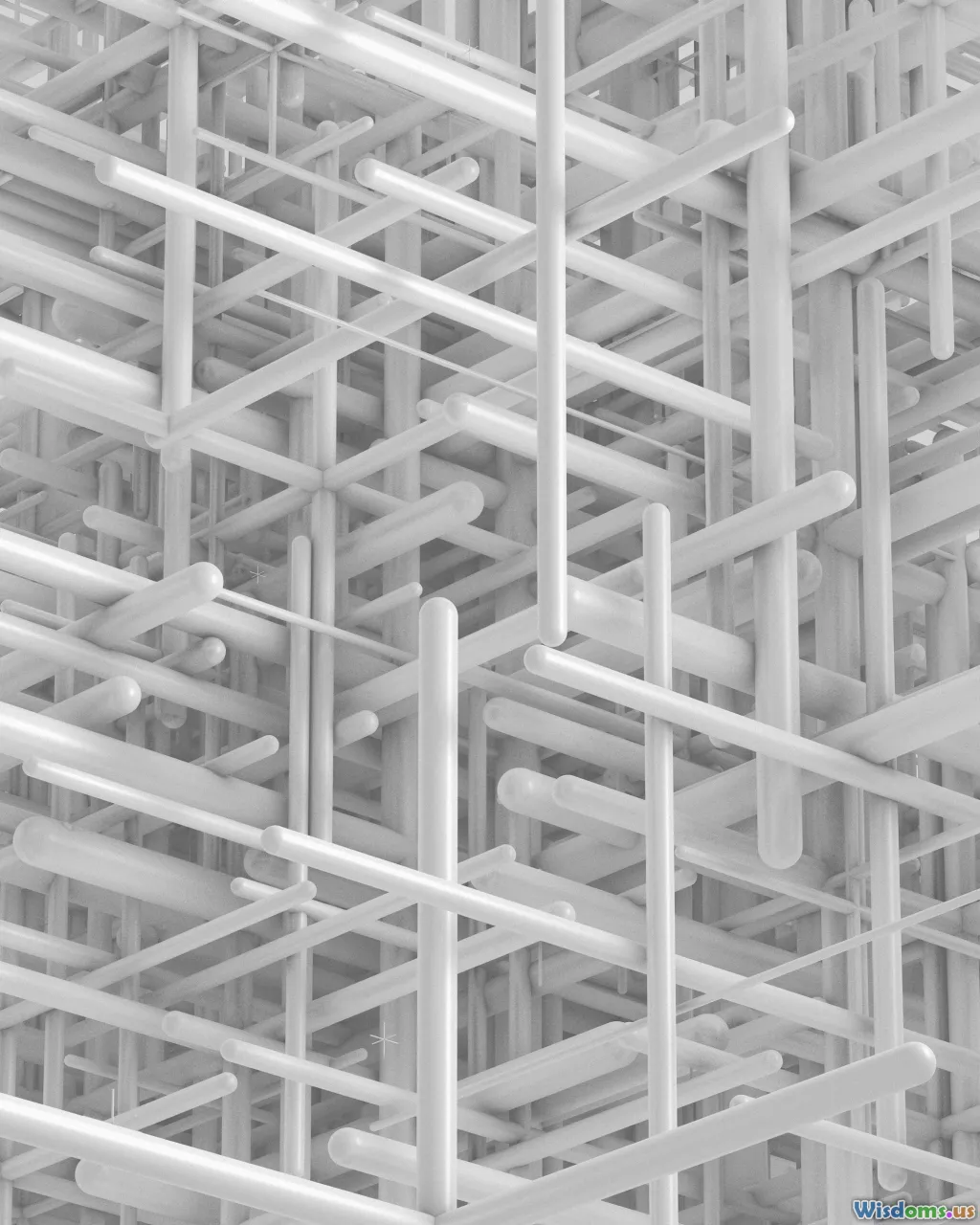

A modular building factory isn’t just any warehouse—it’s a sophisticated facility often spanning thousands of square feet, with climate control, precision machinery, and a skilled workforce. Walking in, you’re greeted by a methodical layout: there are bays for framing, specialty areas for MEP (mechanical, electrical, and plumbing) work, and lines where whole modules move from one stage to another.

In North America and Europe, facilities like those operated by companies such as Katerra or Modulaire Group can produce the equivalent of an entire apartment building in weeks—a process that would traditionally take months or even years. The controlled setting enables consistent quality, protection from weather delays, and efficient use of materials.

Modular demand has soared post-pandemic, with the market size projected to hit $130 billion worldwide by 2031 (Allied Market Research, 2023). This demand has pushed factories to optimize for both speed and flexibility, with some now running advanced robotics and digital 3D modeling systems.

Step 1: Digital Design & Engineering

Everything begins on screen. Using Building Information Modeling (BIM) software, architects and engineers collaborate to create highly detailed digital plans. These go beyond basic blueprints—they specify every stud, screw, routing path, finish, and MEP system.

Key insights:

- Clash Detection: BIM allows engineers to test fitups—anticipating where plumbing could collide with wiring or ducts, so there are no expensive surprises onsite.

- Economy of Scale: Repeating structural components or room designs—such as bathrooms or corridors—lets factories buy materials in bulk, saving time and money.

- Customization: While modular is often seen as "cookie-cutter," digital design allows true customization, with clients frequently able to choose finishes, layouts, and smart technologies before fabrication begins.

For example, Laing O’Rourke's approach in the UK leverages advanced digital twins, enabling them to finalize building specs with clients before a single board is cut.

Step 2: Material Sourcing and Inventory Prep

Next, the raw ingredients arrive. Factories source large volumes of lightweight steel, engineered timber, insulation, and sheetrock—often from certified sustainable suppliers. Materials are delivered to weather-resistant loading docks, then sorted with barcode-driven systems for inventory tracking.

How it works in action:

- Steel for frames is precisely measured and stored on racking systems.

- Timber is kiln-dried, planed, or cut into standardized lengths.

- MEP equipment (like wiring harnesses, conduits, and pipes) is pre-bundled so it’s ready for fast installation down the line.

Advanced factories use just-in-time (JIT) procurement models, minimizing storage space and waste—a stark contrast to traditional construction sites, which must store all materials on-site for months.

Step 3: Structural Framing and Module Fabrication

This is where the building’s bones come together. Specialized stations assemble steel or timber frames using CNC (computer numerical control) saws and welders. Carpenters and fabricators work in tandem, every action coordinated by digital tablet instructions linked to the BIM model.

Typical sequence:

- Wall frames: Assembled with windows and structural supports in place.

- Floor and ceiling frames: Constructed for strength and easy side-by-side joining.

- Shell assembly: Floor, wall, and ceiling frames are unified, encasing insulation and sheathing for rigidity and weather resistance.

In some facilities, robots handle repetitive tasks—like drilling, fastening, or precise saw cuts—ensuring tolerances within millimeters. The use of pre-engineered fixings and laser leveling ensures every module will fit perfectly once shipped to its final site.

A notable example: Blokable's Auburn, WA factory builds prefabricated blocks, or "bloks," that are 90% finished indoors and designed for easy stacking and connection once delivered.

Step 4: Mechanical, Electrical & Plumbing (MEP) Installation

In traditional construction, fitting plumbing and electrical can add weeks to a build. Inside the factory, with modules wide open and easily accessible, specialist teams can install—then inspect—MEP systems in a matter of hours.

Key details:

- Electrical wiring: Pulled through pre-cut grooves, clipped, and tested by licensed electricians.

- Plumbing: Pipes run cleanly with quick-fit connectors—prepressure tested to avoid leaks.

- HVAC units: Compact, energy-efficient systems, often modular themselves, are slotted into pre-designed housings.

Workers have direct access to every angle. That makes diagnosis, corrections, and documentation far simpler than if these systems were jammed into hard-to-reach crawl spaces. Photos and QR code scans tie every step back to the digital BIM model for later reference or certification.

Step 5: Interior and Exterior Finishes

With the structure sealed up and systems in place, attention shifts to the aesthetics. Teams move through the modules, each responsible for a specific finish—creating a seamless, high-end look.

Phase breakdown:

- Drywall or paneling: Hung with mechanical lifts, ensuring flawless seams.

- Flooring: Roll-out vinyl, engineered hardwood, or carpet tiles are quickly installed.

- Paint and trim: Automated sprayers or skilled painters handle walls, after which baseboards and door frames follow.

- Exterior siding and windows: Applied while modules are on fully accessible lines, dramatically simplifying what is usually a weather-dependent outdoor job onsite.

For premier projects, factories can incorporate advanced finishes—such as stone-veneer siding, triple-glazed windows, or millwork cabinetry—as specified in client designs. Quality control is ruthless: modules are rejected if any finish isn’t up to commercial or residential standard.

Step 6: Integrated Technology and Smart Features

Modern modular builds frequently come with integrated technology out of the box. This can range from digital thermostats, built-in speakers, and advanced security, to touch-controlled lighting and network cabling.

Examples in use:

- Volumetric Building Companies offer modular hotel rooms ready with digital locks, smart TVs, and Wi-Fi hubs installed before arrival.

- IoT (Internet of Things) devices—such as water leak detectors, solar panel controllers, and smart HVAC—can be trialed on-site, ensuring seamless functionality upon delivery.

Pre-installation of such technology greatly reduces expensive, disruptive retrofits post-occupancy. Buildings leave the line virtually ready for immediate use, a significant market enhancement in competitive sectors like student accommodation and co-living.

Step 7: Rigorous Quality Control & Inspection

No module advances to the next stage without passing detailed inspections, rivaling those of high-tech manufacturing. Digital checklists ensure hundreds of parameters—structural tolerances, service installations, materials specs—must be greenlit by designated supervisors.

Typical protocols:

- Testing: Modules face thermal, acoustic, and weather sealing tests. MEP systems are pressure- and voltage-tested to code compliance;

- Finishes: Paintwork, joinery, and exterior aesthetic must match formal mock-ups accepted by the client;

- Certifications: Every factory is regularly audited to meet ISO 9001 and, in some regions, additional green building or local code requirements (such as California’s CALGreen standards for sustainability).

Serialized QR codes attached to each unit help with both traceability and future maintenance. If a module fails, it’s sent back along the line for fixed-point revision before retesting.

Step 8: Final Assembly, Modular Integration & Wrap

In this critical stage, modules are prepped for shipment and, if they are part of bigger blocks (e.g., classrooms or apartments), partially assembled in clusters. This might include docking corridors, stairwells, or joining modules into larger living spaces.

Modules are sealed up using heavy-duty shrink wrap or weather-proof tarping, with padded guards fitted to protect windows and exterior features in transport. Final labeling, project checklists, and a just-in-time log are attached for delivery teams. Throughout, logistics specialists plan timing down to the hour, minimizing storage time and on-road delays.

Step 9: Loading, Transportation, and Delivery

Moving a completed section of building—some as much as 70 feet long and weighing 60,000 pounds—requires real choreography.

Core process:

- Transport: Modules are crane-lifted onto flatbed trucks with custom braces to avoid flexing in transit.

- Route planning: Transport specialists map journeys, often traveling overnight to avoid major roadways and ensure modules are delivered intact to tight urban sites.

- Arrival: At site, a crane operator, working from BIM-generated lifting plans, hoists the modules directly into place in a matter of hours.

A striking example: when Brooklyn’s 461 Dean Street apartment tower was constructed, each of its 930 modules arrived overnight from a Pennsylvania factory and was craned into place—sometimes at a pace of 10 units per day (NY Times).

Step 10: Onsite Installation and Final Connection

Unlike conventional builds, where months might pass before a building is structurally complete, modular installations are lightning fast.

Here’s how factories and site teams collaborate:

- Stacking and joining: Modules are anchored upon pre-laid foundations, joined horizontally and vertically using engineered fasteners.

- Final connections: Utility tie-ins (water, power, internet) are snapped to access points set in the factory—reducing risk and cutting labor time.

- Quality inspection: Site supervisors walk through to ensure fit-and-finish still meets standards and that no damage occurred during transport or lifting.

In some cases, as with emergency housing post-disaster, families can move in within days of site installation—a life-changing speed compared to brick-and-mortar construction.

Efficiency and Sustainability Advantages

Modular factories don’t just make buildings faster; they do it with impressive green credentials:

- Reduced waste: Factory builds slash material waste by up to 90% compared to conventional sites, mainly through precise cutting, off-cut reuse, and better recycling (Waste & Resources Action Programme).

- Energy efficiency: Controlled settings produce tighter envelopes and better insulation, which translates to lower energy bills for occupants.

- Design flexibility: Easy integration of rooftop solar, rainwater harvesting, or living walls start right in the factory.

Prominent sustainable builds include McDonald's net-zero drive-thru in England, which used factory-built panels, LED lighting, and grass roof modules, demonstrating that sustainability and modularity can work hand in hand.

The Future: Automation and Beyond in Modular Construction

Factories are already pioneering new technologies poised to revolutionize the sector further:

- Advanced robotics: Machine arms and automate lifts for repetitive jobs, boosting consistency.

- AI scheduling: Machine learning software predicts delays, managing supply chains and workflow bottlenecks in real time.

- 3D printing: Some lines now use large-scale 3D printers to create entire façade panels, stairs, or concrete forms directly from digital models—with the goal of reducing labor even further.

For example, Dubai’s AMANA Modular Construction has piloted fully robotized lines where most manual steps—apart from quality inspection—have become autonomous, signaling a bold leap toward industry 4.0.

From the first digital sketch to the final crane drop at the building site, modular construction—driven by dedicated factories—unlocks both speed and uncompromising quality. Innovators worldwide are shaping the future of the built environment, one module at a time. Whether you’re a designer, developer, or a prospective tenant, exploring inside a modular factory offers a glimpse not just into how buildings are made, but into the possibilities for smarter, greener living.

Rate the Post

User Reviews

Popular Posts